Proficiency

SENHO TECH Proficiency

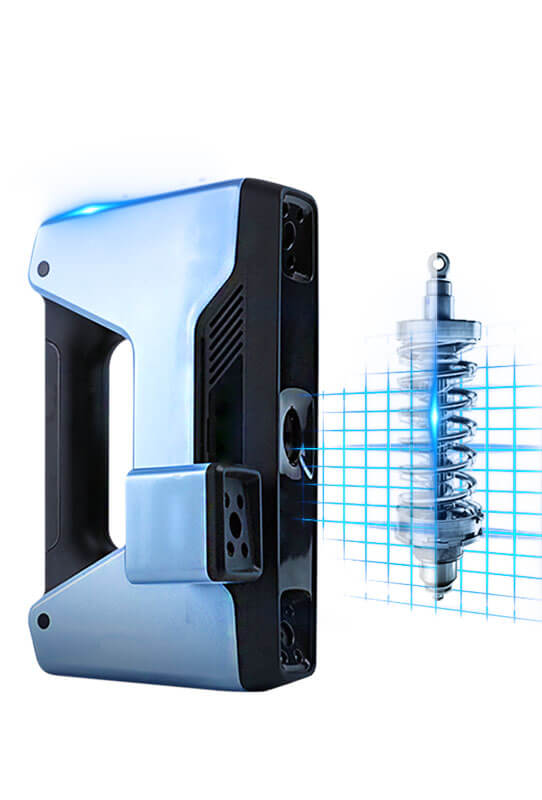

•CAD Design •3D Scanning

Our team can ensure high-quality production, design new products according to customer requirements, and improve product performance.

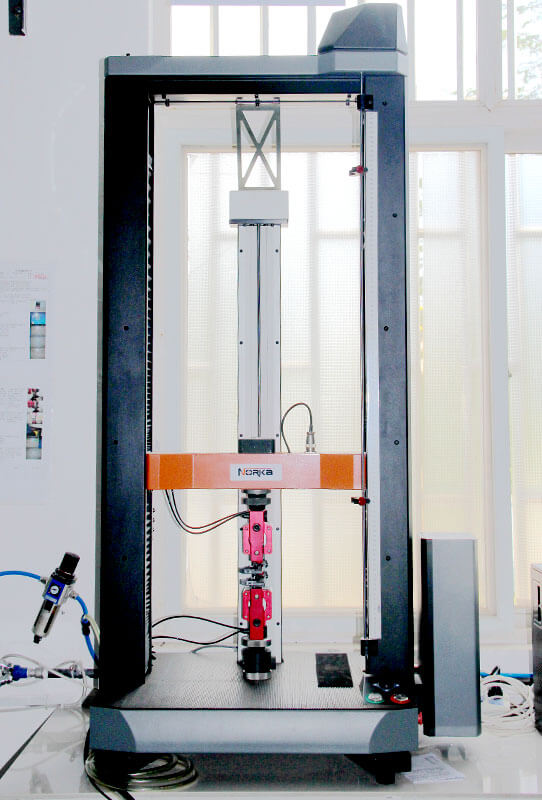

•In House Tensile Testing •Air Spring Crimping & Burst Testing

Assembly & Quality Control

Experienced craftsmen assemble and test products using state of the art equipment. Products can be customized to suit your configurations and specifications.Deliver orders on time and with good quality.

Test Conditions

1. After vulcanization, airbag rubber should be adjusted and tested under the conditions specified in GB/T2941.

2. The airbag rubber should be placed at -40°C for at least 16 hours before the low temperature test, and other tests should be placed at room temperature before the test at least 6hours.

Test Equipment

The physical and mechanical performance test of the rubber compound is carried out on the corresponding equipment according to the provisions of.

3D Scaning

Plate Vulcanizing Press

Gas Tightness Tester

Fatigue Life Tester

Tensile Tester

Heat Aging Tester

Rheometer

Mooney Viscometer

Test Method

1. Tensile test

The tensile strength, elongation at break and permanent deformation test of the airbag compound shall be tested in accordance with the provisions of GB/T528, using a type 1 dumbbell-shaped sample conduct.

2. Compression set test

The compression set test of airbag rubber is carried out according to the method specified in GB/T7759.

3. Hardness test

Airbag rubber hardness test shall be carried out according to the provisions of GB/T531.1.

4. Flex test

The flex test of the airbag rubber is in accordance with the provisions of GB/T13934, and the sample is bent 1 million times at a rate of (300±10) times per minute. Check the specimen for cracks in the groove.

5. Low temperature performance test

The low temperature resistance performance test of the airbag compound is carried out in accordance with the provisions of GB/T1682, and the brittleness temperature of the compound is measured.

6. Hot air aging test

The hot air aging test of the airbag rubber is carried out in accordance with the provisions of GB/T3512, using a type 1 dumbbell-shaped sample to determine the aging properties of the rubber after thermal aging.

Tensile strength change rate, elongation at break change rate and hardness change.

7. Ozone aging resistance test

The ozone aging resistance test of the airbag rubber material is carried out according to the method A specified in GB/T7762, and the test condition is ozone concentration (50±5)×10-8 (volume fraction), the test temperature is (40±2)°C, so that the sample has an elongation of (20±2)%, and the storage time is 72h.